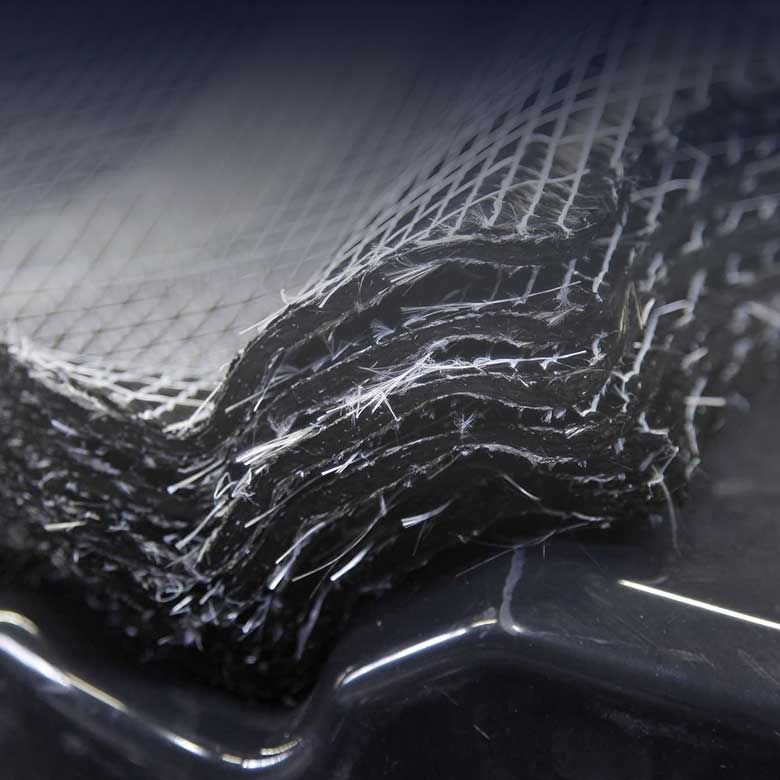

Tomo Industrial CT can be used for porosity analysis of composite materials (e.g., pore volume and distance from the surface), fiber and resin analysis in local fiber, fabric, and roving directions, as well as derived statistical data such as orientation histograms or orientation tensors, fiber volume fraction, and porosity within the resin. All data can be exported to finite element analysis tools to improve material modeling and structural simulation, enabling the creation of comparative models for R&D and component design.

In the aviation sector, with the continuous emergence of innovative materials, the internal quality inspection of aircraft components has become increasingly important. The complex structures and performance requirements of these materials necessitate in-situ detection of internal defects and dimensions during maintenance. Tomo Industrial CT technology, with its exceptional flexibility and precision, offers a high-quality inspection solution for AM, composite materials, engine blades, and other materials. This technology is not limited by the shape or material of the inspected items, meeting customers' demands for high-precision 3D inspection.

Tomo Industrial CT allows for in-depth observation of the internal structure of materials and batteries, enabling researchers to comprehensively consider the material structure, preparation process, and assembly techniques. It helps promptly and effectively identify failure causes, thereby improving battery production processes to enhance quality.

In the automotive manufacturing sector, Tomo Industrial CT scanning technology plays a crucial role. It accurately presents cross-sectional imaging of automotive components and products, achieving precise non-destructive localization and measurement of defects with high detection sensitivity and spatial resolution. Automotive systems are complex combinations of mechanical and electronic components. Materials such as plastics, rubber, aluminum, steel, alloys, and composites used in automotive manufacturing can be comprehensively analyzed in 3D using X-ray CT scanning.

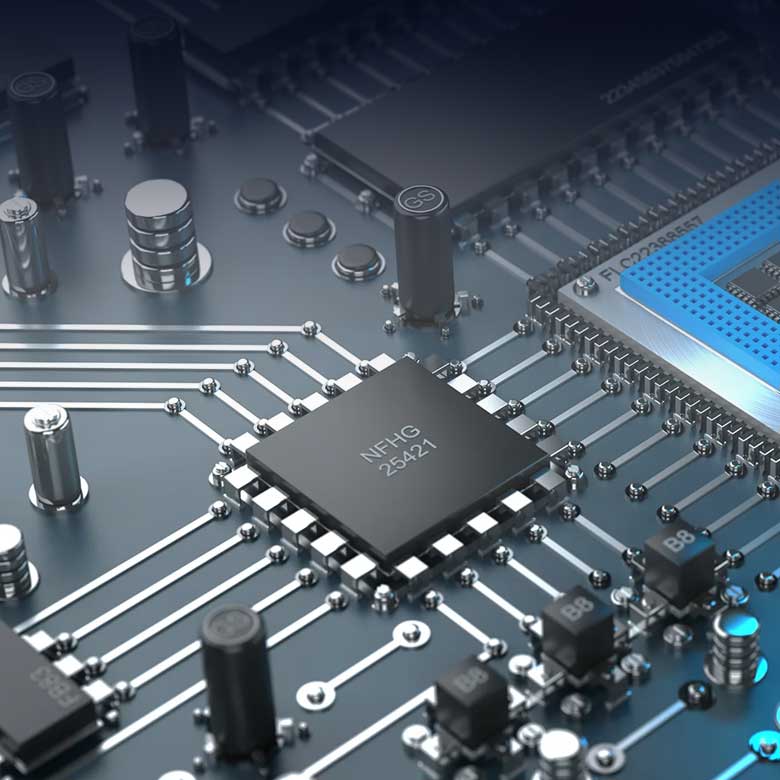

Failure analysis of components is crucial for ensuring product quality and longevity. Using Tomo Industrial CT testing technology for failure analysis allows for accurate determination of failure characteristics, identification of causes, and provides a scientific basis for process improvement and design optimization. Non-destructive testing technology can address various issues in electronic component failure analysis, including the detection and localization of internal defects, voids, foreign objects, circuit connections, chip delamination, solder joints, and welding traces, as well as excess material and quality issues during processing, such as lead crossing, bending, chip cracks, and voids.

This system is currently the most compact and comprehensive teaching demonstration and laboratory CT system with the most complete degree-of-freedom axis system. It is specifically designed for educators and researchers who need to deeply understand CT co

This system is a compact CT system that integrates functions typically found in larger-scale CT systems. It can be configured with microfocus or nanofocus X-ray sources, making it highly suitable for high-precision inspection of lightweight small workpiec

This system is a general-purpose CT system that can be configured with both microfocus and nanofocus X-ray sources, combining high penetration and high resolution. It is suitable for high-precision inspection of medium/small workpieces with medium/high de

This system is a large-scale CT system that can be configured with microfocus and small-focus X-ray sources, featuring high energy, high resolution, and high versatility. It is suitable for high-precision inspection of medium/large and high-density workpi

Utility Model Patent

Domestic Customers Have Been Served

Invention Patent

Government/Industry Awards

Foreign Customers Have Been Served

R&D Personnel Ratio

#Industry News

2The semiconductor industry faces significant challenges in meeting the growing demand for high efficiency and product quality.

#Company News

1The semiconductor industry faces significant challenges in meeting the growing demand for high efficiency and product quality.

#Academic Exchange

3The semiconductor industry faces significant challenges in meeting the growing demand for high efficiency and product quality.