Unlike conventional coordinate measurement techniques, such as contact and optical methods, industrial CT metrology operates on digital models, enabling the simultaneous analysis of multiple features without extending scan time. Tomo Industrial CT technology can perform various tests on a single CT dataset, such as dimensional measurement and material analysis. Additionally, CT technology demonstrates its uniqueness in product assembly by non-invasively capturing all geometric details, helping manufacturers achieve quality control throughout product development and manufacturing. Now, whether products are manufactured through die casting, machining, laser cutting, 3D printing, injection molding, or assembly, CT technology can be used to obtain internal structural features and dimensional information, further optimizing manufacturing processes.Now, products manufactured through processes such as die casting, machining, laser cutting, 3D printing, injection molding, and assembly can all

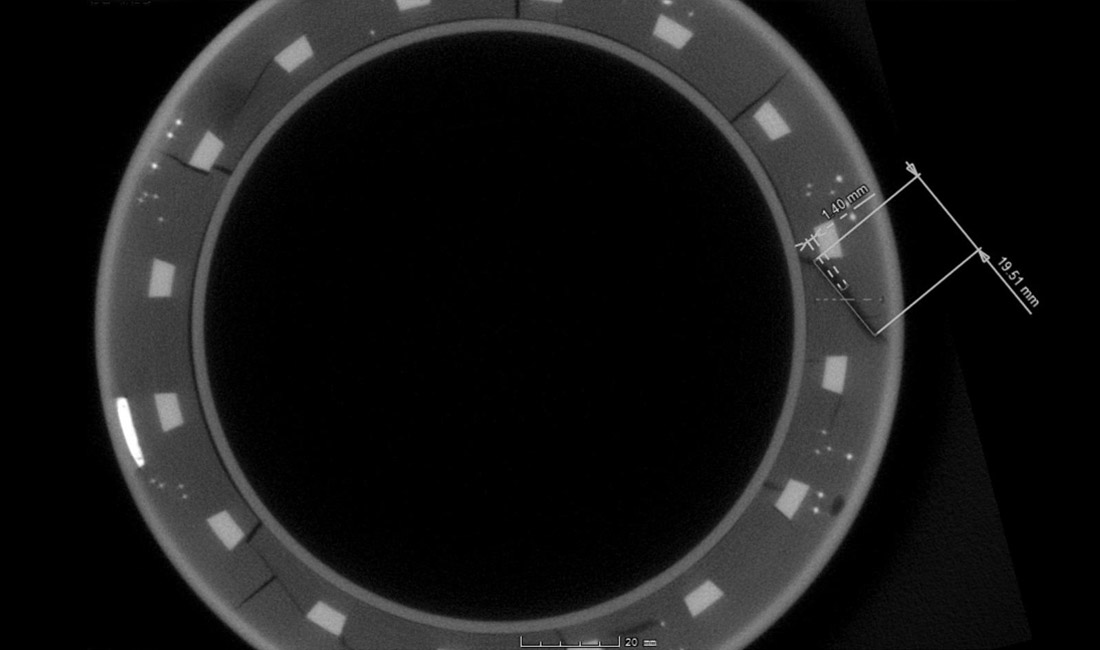

Assembly Dimensional Measurement

Unlike conventional coordinate measurement techniques, such as contact and optical methods, industrial CT metrology operates on digital models, enabling the simultaneous analysis of multiple features without extending scan time. Tomo Industrial CT technology can perform various tests on a single CT dataset, such as dimensional measurement and material analysis. Additionally, CT technology demonstrates its uniqueness in product assembly by non-invasively capturing all geometric details, helping manufacturers achieve quality control throughout product development and manufacturing. Now, whether products are manufactured through die casting, machining, laser cutting, 3D printing, injection molding, or assembly, CT technology can be used to obtain internal structural features and dimensional information, further optimizing manufacturing processes.

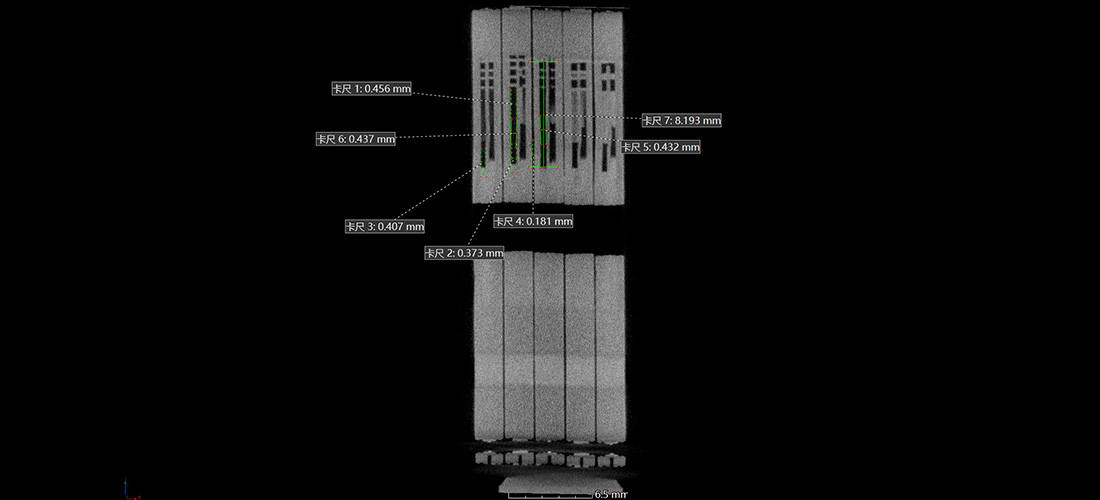

Battery Dimensional Measurement

Using computed tomography (CT) technology, we can perform internal 3D imaging and precise dimensional measurement of electric vehicle batteries. This technology can detect key parameters such as battery size, shape, structure, and assembly accuracy with extremely high precision, providing solid data support for battery manufacturing and quality control.

CT technology allows us to accurately measure various dimensions of batteries, including their shape and internal structure, which is crucial for ensuring battery performance and safety. With this technology, we can perform multiple analyses on the same dataset, such as dimensional measurement and material testing, which not only improves efficiency but also ensures data consistency and accuracy.

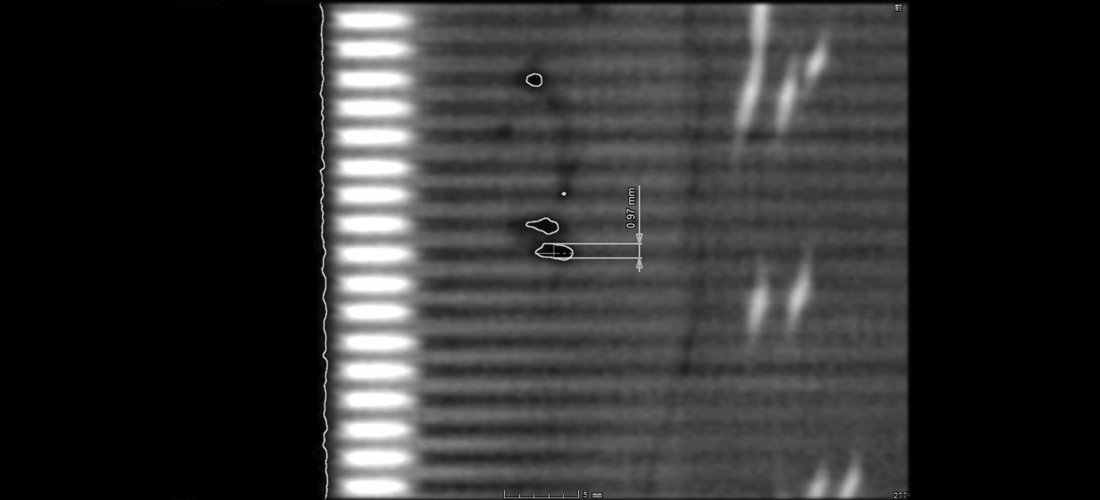

Porosity Defect Measurement

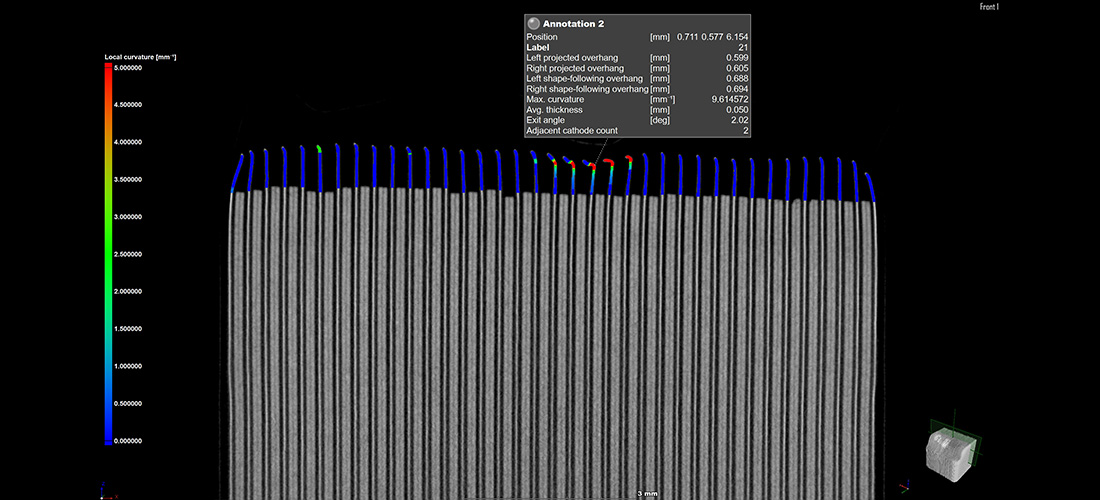

Industrial CT can not only be used to detect the manufacturing quality of blades but also to measure manufacturing dimensional deviations, which may affect airflow, reduce combustion efficiency, and lead to issues such as decreased turbine power and increased fuel consumption.