Tomo Industrial CT can be used for porosity analysis of composite materials (e.g., pore volume and distance from the surface), fiber and resin analysis in local fiber, fabric, and roving directions, as well as derived statistical data such as orientation histograms or orientation tensors, fiber volume fraction, and porosity within the resin. All data can be exported to finite element analysis tools to improve material modeling and structural simulation, enabling the creation of comparative models for R&D and component design.

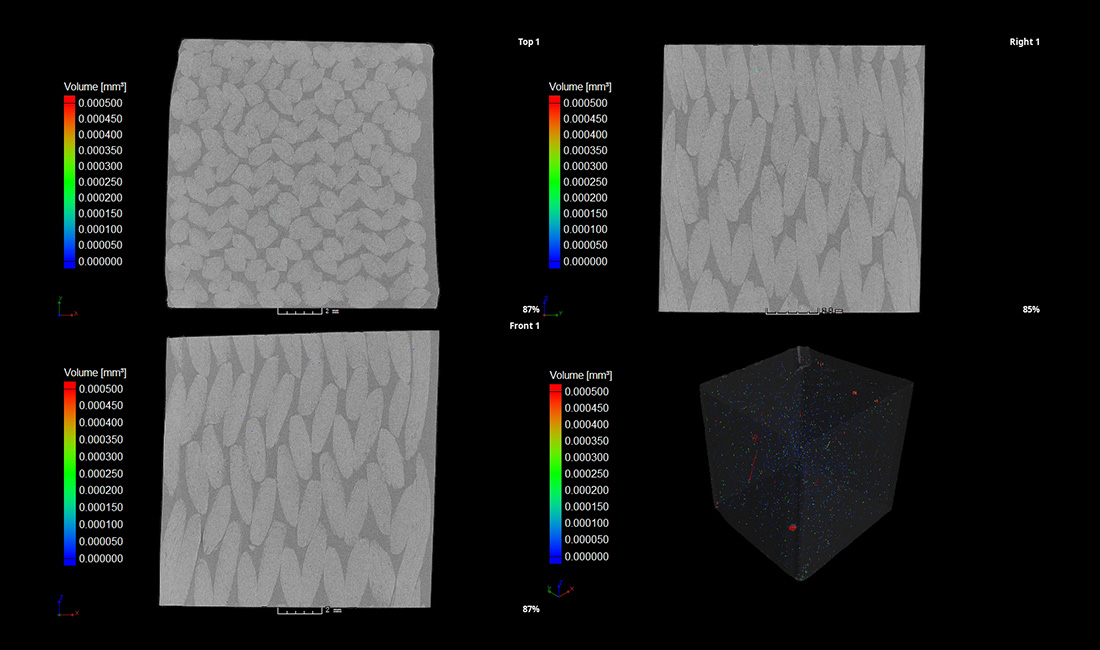

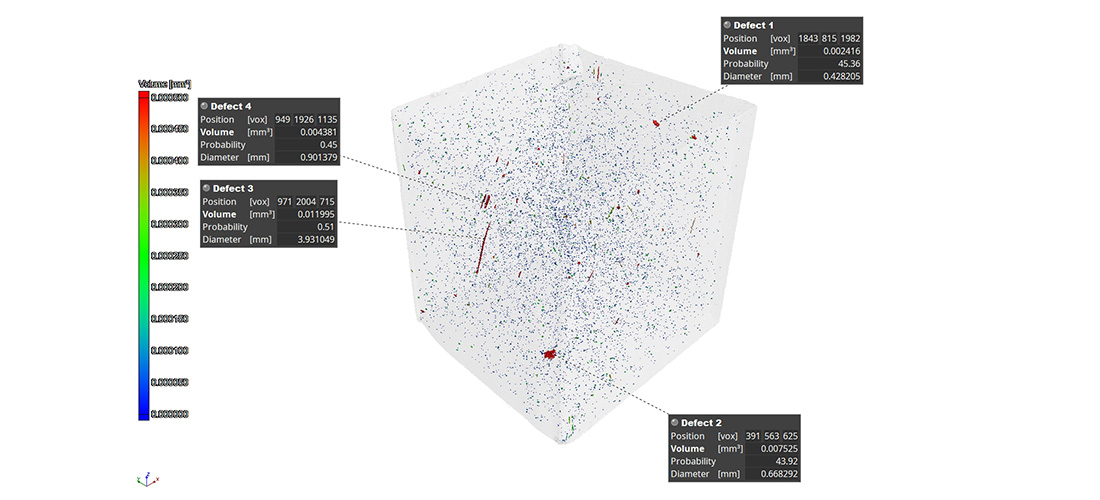

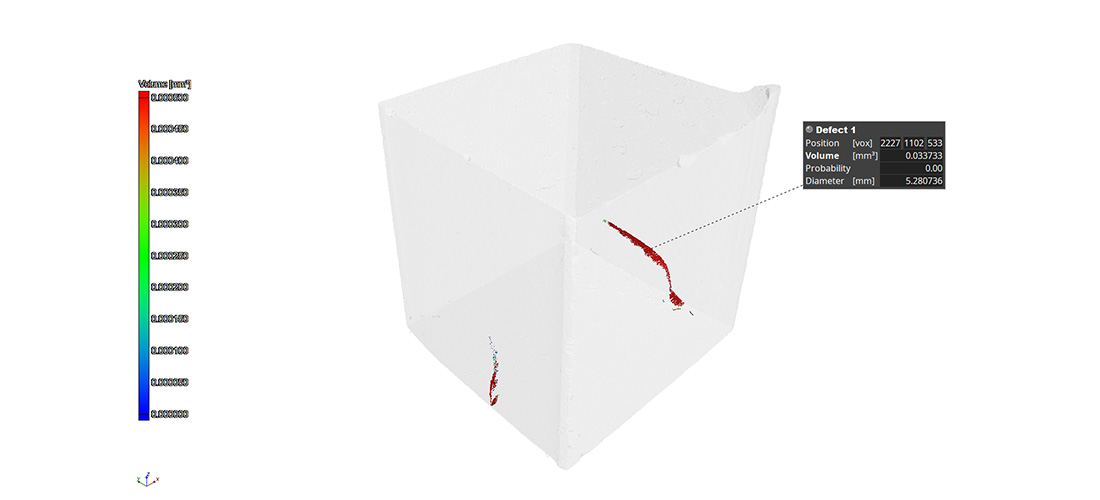

Porosity Analysis

Porosity is one of the common manufacturing defects in composite materials, and porosity rate is a quantitative indicator of internal quality. Tomo Industrial CT provides detailed characterization of the size and distribution of internal pores in composite materials.

Measurement Analysis

The comprehensive capabilities of CT scan data analysis for composite material structures are extensive. Any structure can be captured and characterized according to its design intent, including local fiber, fabric, and roving direction analysis, fiber volume fraction, and porosity within the resin.

In-Situ 4D

Tomo Industrial CT equipped with in-situ 4D capabilities helps researchers better understand the internal 3D structural changes of materials under different temperature and stress conditions.