In the aviation sector, with the continuous emergence of innovative materials, the internal quality inspection of aircraft components has become increasingly important. The complex structures and performance requirements of these materials necessitate in-situ detection of internal defects and dimensions during maintenance. Tomo Industrial CT technology, with its exceptional flexibility and precision, offers a high-quality inspection solution for AM, composite materials, engine blades, and other materials. This technology is not limited by the shape or material of the inspected items, meeting customers' demands for high-precision 3D inspection.

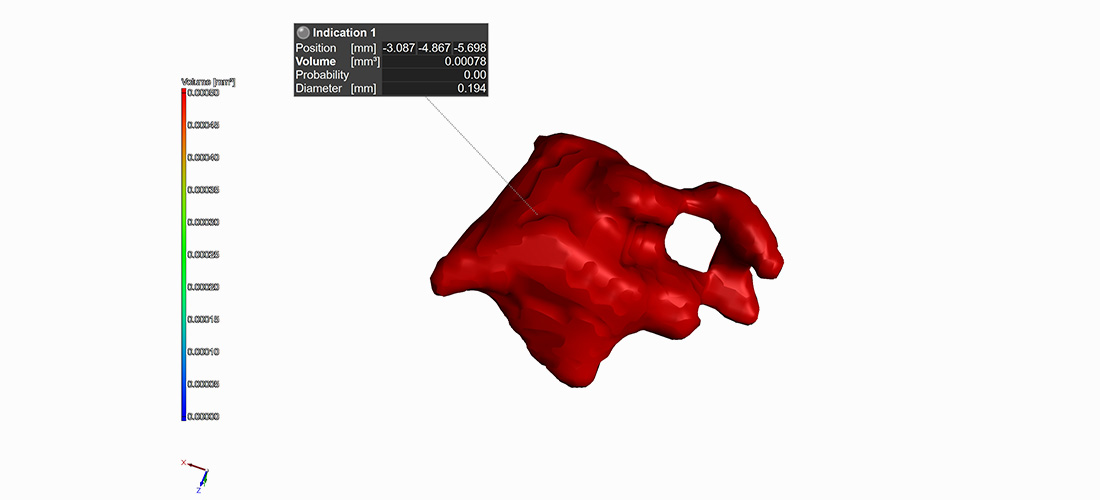

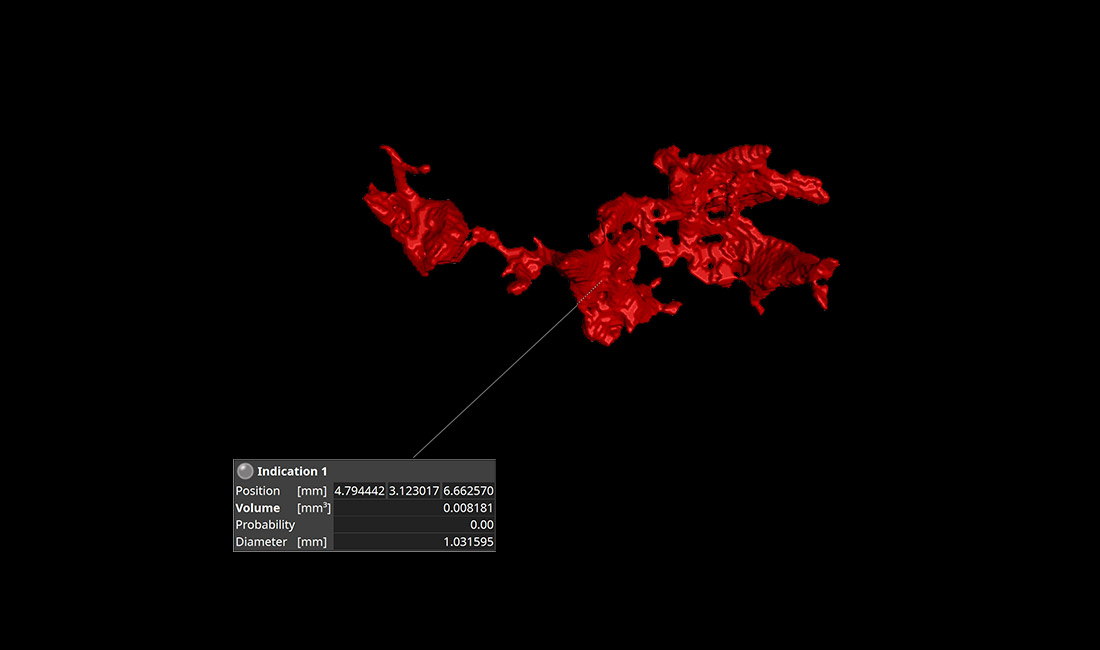

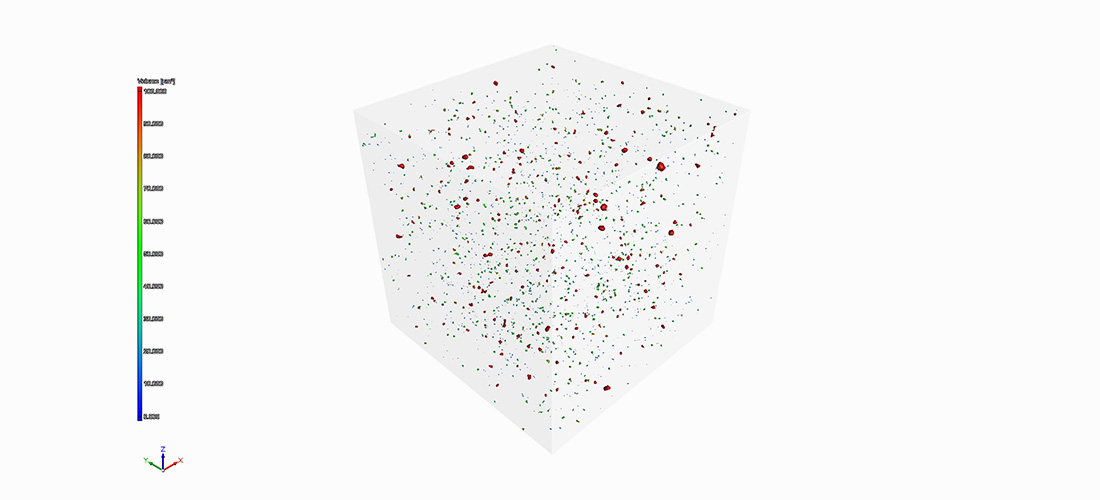

3D Printed Metal - Porosity Analysis

Laser additive manufacturing uses high-energy laser beams as the energy source to melt and prepare high-entropy alloys. It not only achieves a perfect combination of high strength and high ductility but also enables the production of larger, more complex, and high-temperature-resistant high-entropy alloy parts for engineering applications. Refractory high-entropy alloy additive manufacturing technology is a critical component of aero-engine development and is widely used in the aerospace industry.

In the additive manufacturing industry, Tomo Industrial CT is often used for the following aspects: metal powder hollowing, inclusion testing, internal porosity analysis, reverse engineering, model comparison, and geometric measurement.

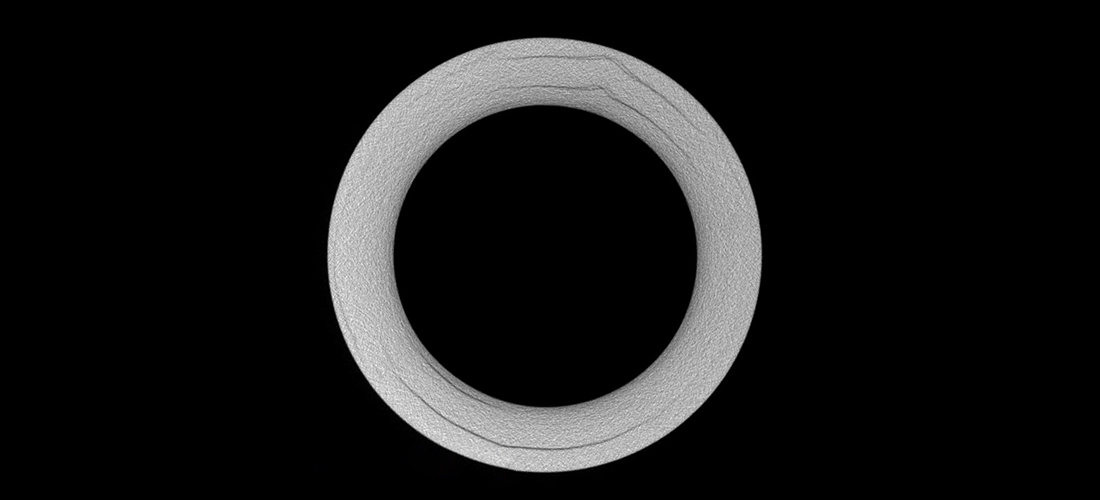

Aerospace Engine Nozzle - Crack Analysis

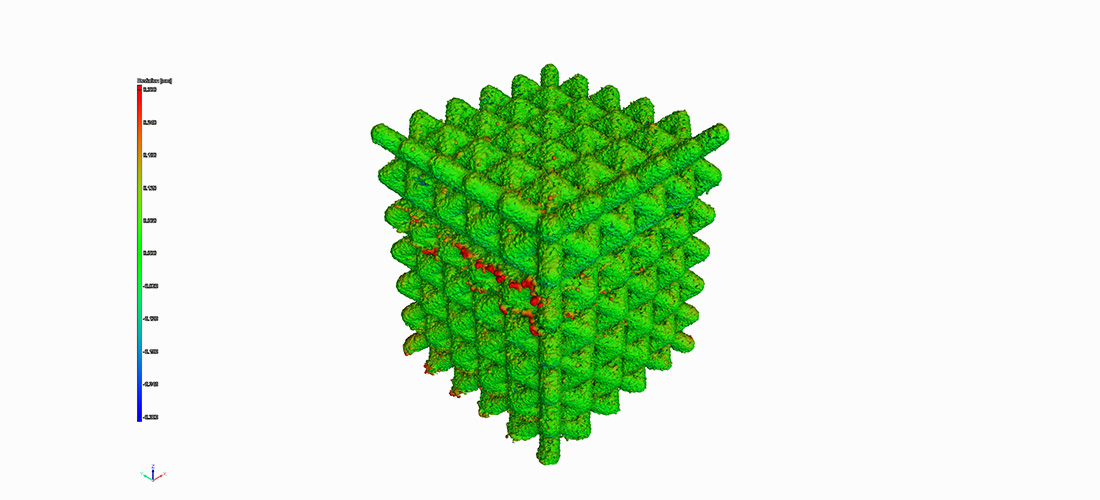

Titanium Alloy Printed Mesh - Model Comparison

The data results obtained from Tomo Industrial CT scans can also serve as the basis for simulating the printing process and optimizing process parameters. The ultimate goal is to ensure that the manufactured actual parts are as close as possible to the CAD model for subsequent surface treatment and assembly. The number, size, and shape of defects can be combined with finite element analysis to simulate the stress distribution of parts under load and assess the integrity of structural components in service.

Single Hole Morphology Analysis

The aerospace industry requires inspection of each component of critical products for defects according to specifications, such as pores in fiber deposition, delamination, ripples, tensile fracture cracks, micropores, fatigue sample cracks, and creep sample voids, through 3D imaging.