X-ray Source

Mini-Focus Tube Voltage(Max.)

320kv/450kV/600kV

Micro-Focus Tube Voltage(Max.)

225kV/240kV/300kV[Option]

Focal Spot 1

225kV/240kV/300kV 4~6μm

Focal Spot 2

320kV: 0.4mm@700W/1.0mm@1500W (EN 12543)

Focal Spot 3

450kV: 0.4mm@700W/1.0mm@1500W (EN 12543)

Focal Spot 4

450kV: 60/100/250/350/450μm@50/100/250/350/450W

Focal Spot 5

600kV: 0.5mm@700W/1.5mm@1500W (ASTM E1165-12)

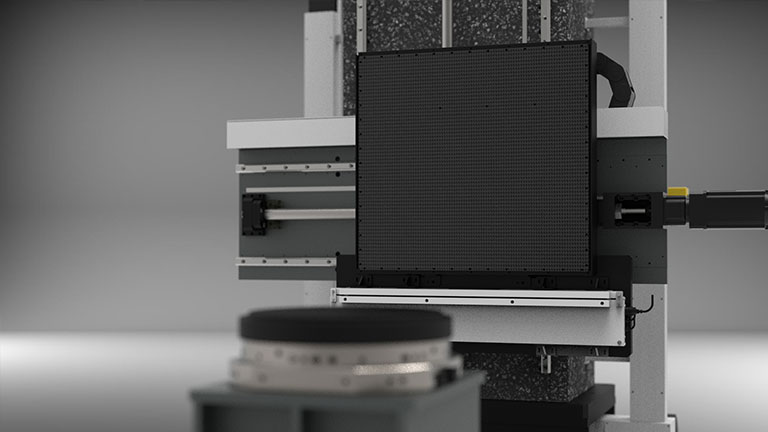

Detector

Type

Amorphous silicon flat panel detector | Linear array detector[curved/straight-line]

Pixel Size

100μm/140μm/200μm | 200μm

Imaging Size

≥400*400mm | ≥640mm/820mm

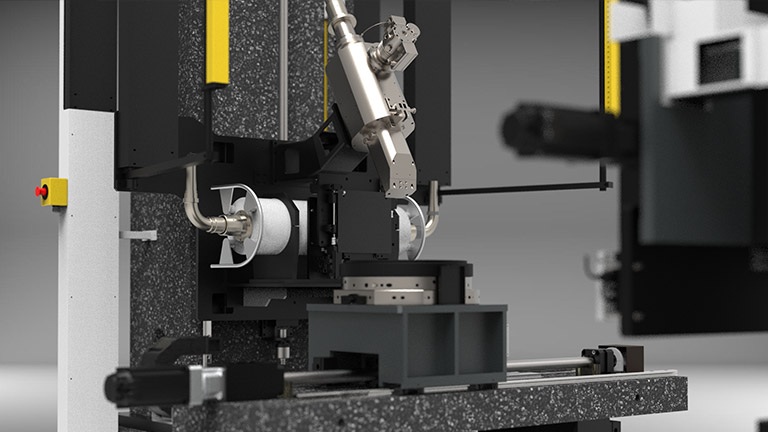

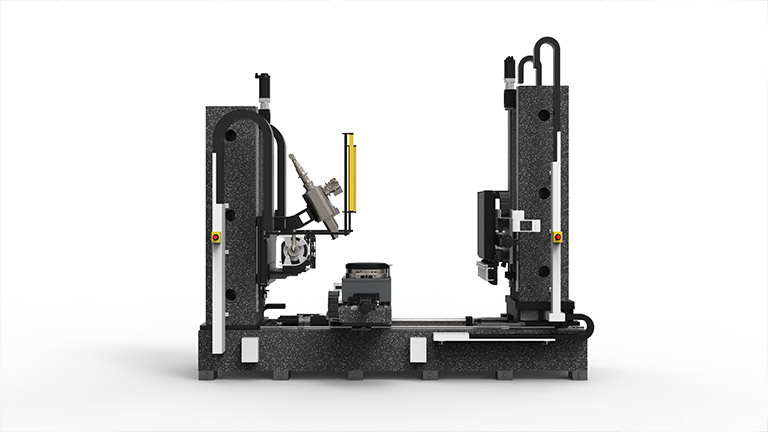

Mechanical System

Manipulation

7 axes

FDD

≥1400mm[micro-focus]/2000mm[ mini-focus]

System Material

Precision granite

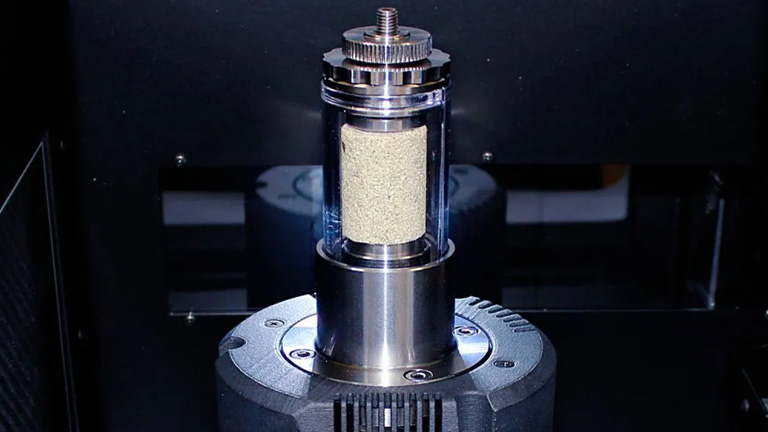

Inspection Sample

Sample Size(Max.)

Ø900×H1000mm

Sample Weight(Max.)

100kg[Customizable]

Lead Cabinet

Size

L5400×W4030×H4000mm

Weight

~45t[@450kV] / ~70t[@600kV]

Software

Cone Beam DR/CT Scanning Reconstruction

Detector calibration management module/Detector calibration scanning module/Batch DR scanning management module/Batch DR scanning module/CT scanning mode management module (Standard third-generation CT 3CT, Rotary table offset extended third-generation CT ROE3CT, Limited-angle CT LA3CT)/Batch CT scanning module/CT reconstruction module

2D Image Processing

Basic image processing functions, marking measurement functions, enhancement functions/image/file output/database management etc

3D Image Display

Data import, data management, CT data visualization, measurement annotation, data alignment, contour extraction, pore analysis, wall thickness measurement, CAD/physical object comparison/report module etc