Failure analysis of components is crucial for ensuring product quality and longevity. Using Tomo Industrial CT testing technology for failure analysis allows for accurate determination of failure characteristics, identification of causes, and provides a scientific basis for process improvement and design optimization. Non-destructive testing technology can address various issues in electronic component failure analysis, including the detection and localization of internal defects, voids, foreign objects, circuit connections, chip delamination, solder joints, and welding traces, as well as excess material and quality issues during processing, such as lead crossing, bending, chip cracks, and voids.

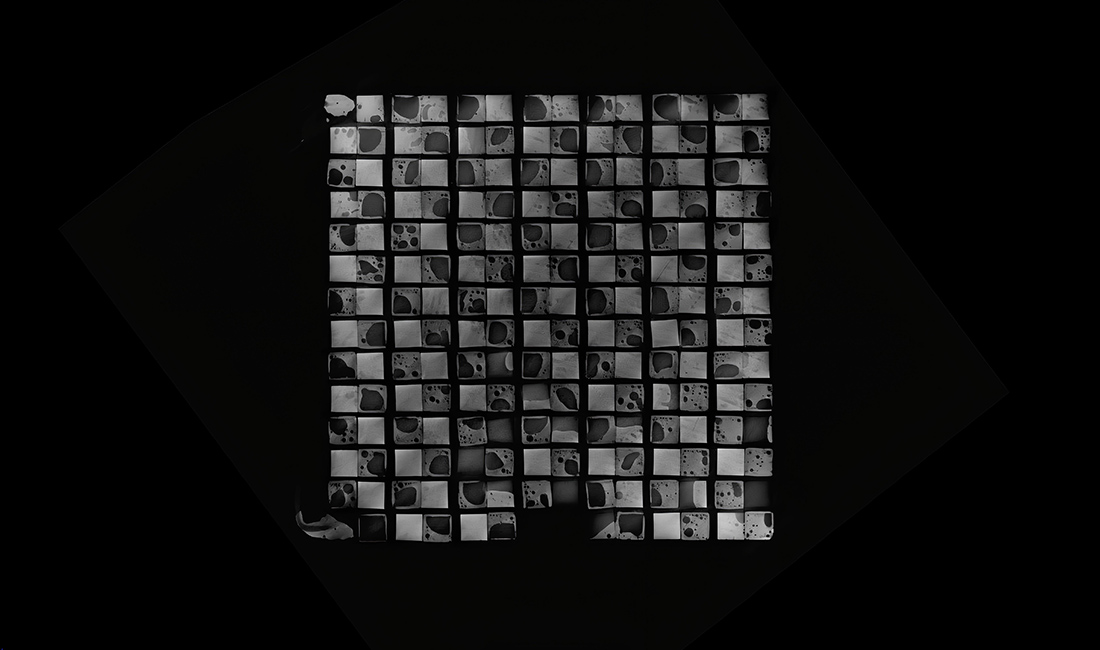

芯片焊接-孔隙CT图

在集成电路半导体行业中,Tomo工业CT主要用于非破坏性高精度检测,通过三维成像技术识别芯片内部微米级缺陷(如裂纹、焊点空隙、互连短路等),验证封装结构完整性及工艺一致性,同时支持逆向工程与数字化建模;相比传统二维检测或破坏性切片,其无损、全视角和自动化分析优势显著提升芯片良率,尤其在先进封装技术(如3D堆叠)中保障高密度互连质量,成为半导体制造全流程质量控制的关键工具。

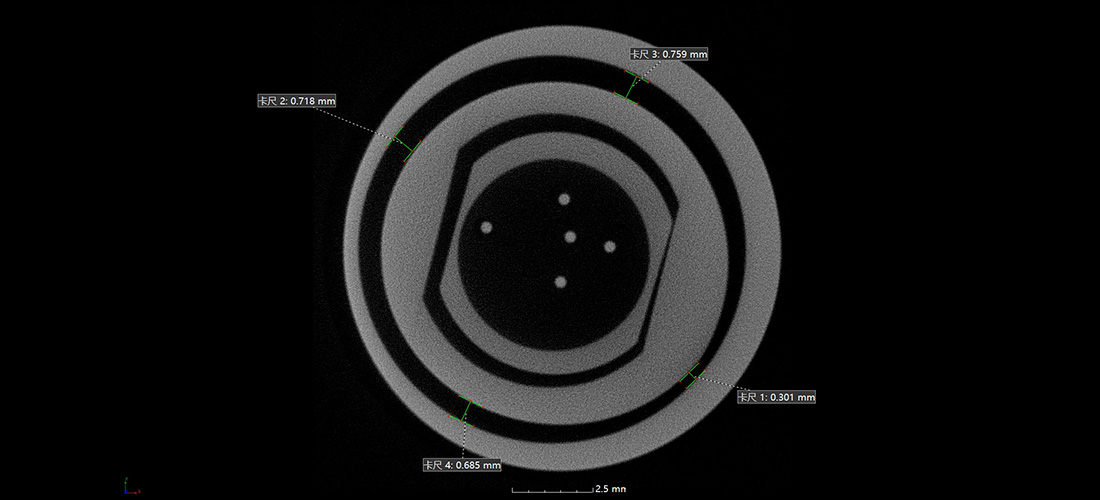

传感器-尺寸测量

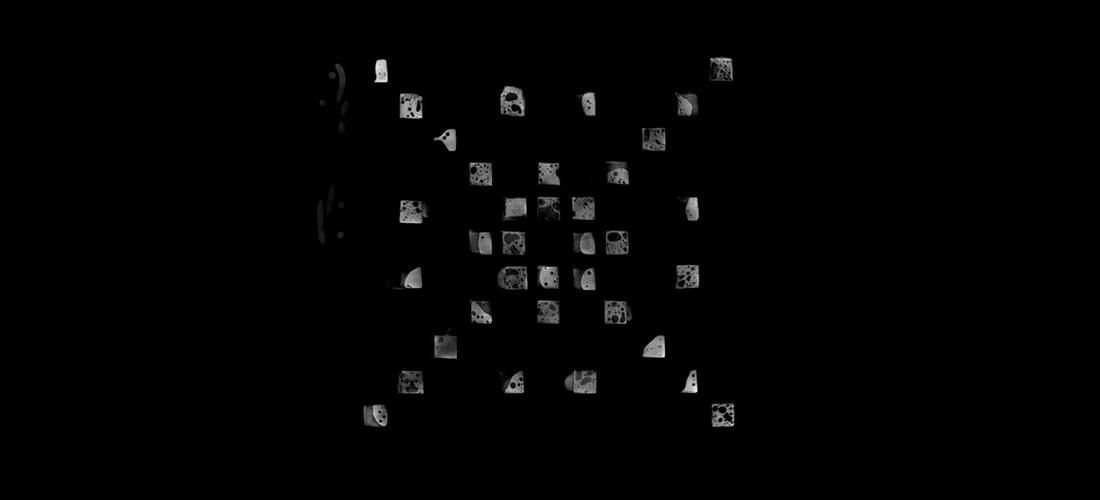

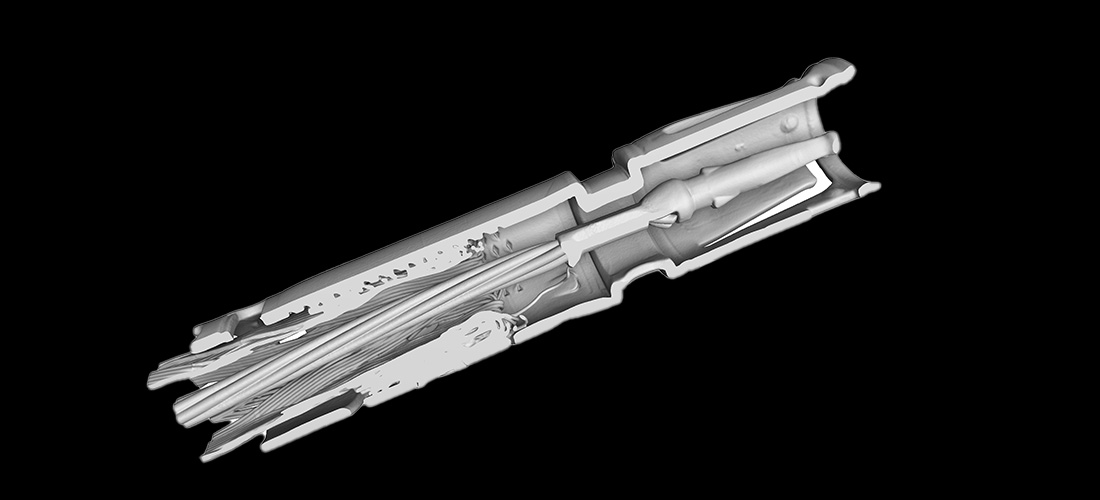

Automotive Connector - Short Circuit Failure Analysis

The main factor causing electrical connector failure is changes in contact resistance, manifested as fluctuating contact resistance, abnormal heating, oxidation, burning, and open circuits. In severe cases, insulation is damaged, leading to short circuits and fires. Insulation abnormalities in vehicles trigger alarms, reduce voltage resistance, cause insulation breakdown, short-circuit burning, and even vehicle fires.

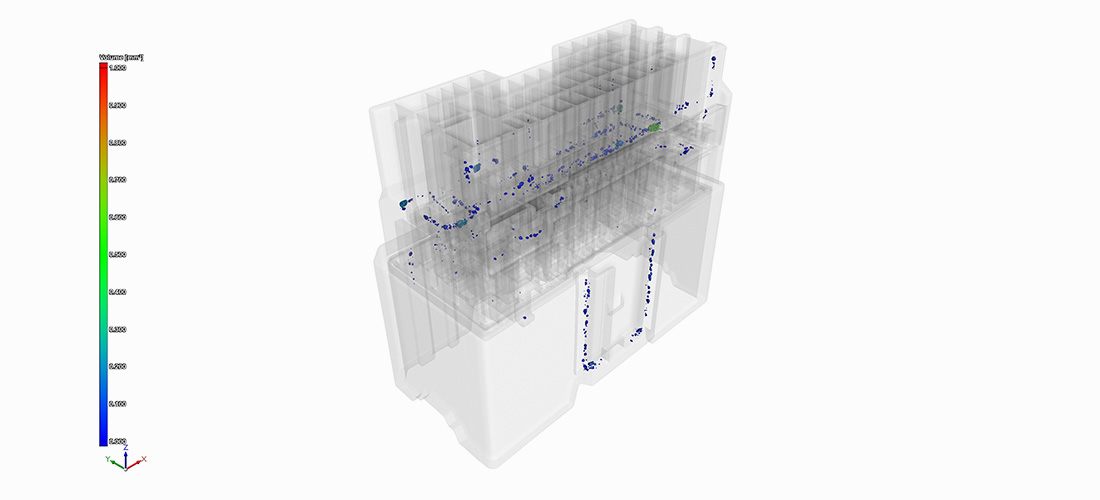

Automotive Connector - Defect Analysis

Automotive connectors are used for transmitting and controlling electrical signals in vehicles, serving as the fundamental components for electrical connections between wire harnesses and between wire harnesses and electrical equipment, enabling the connection and disconnection of power. Reliable contact of conductor contacts, reliable electrical insulation, and reliable mechanical connections in automotive connectors ensure the reliable transmission of electrical signals and effective control of components.

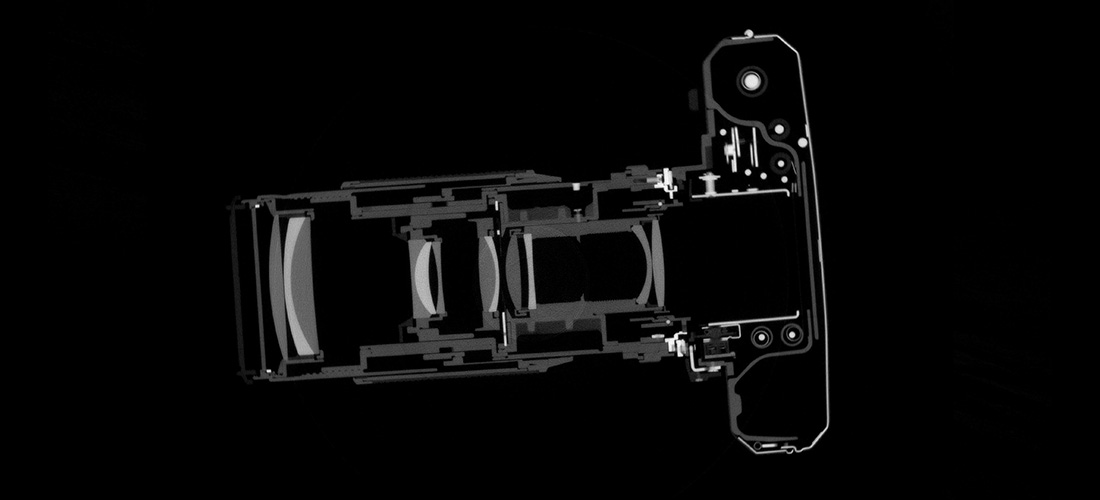

Camera - CT Cross-Section

In addition to assessing the quality of finished products, Tomo Industrial CT systems can help camera manufacturers evaluate the variability of molded products, detect voids and cracks, observe fiber orientation in reinforced plastics, identify defects in assembly states, analyze competitor products, and inspect defects in electronic substrates.