Tomo Industrial CT allows for in-depth observation of the internal structure of materials and batteries, enabling researchers to comprehensively consider the material structure, preparation process, and assembly techniques. It helps promptly and effectively identify failure causes, thereby improving battery production processes to enhance quality.

Laminated Battery - Electrode Inclusion

Internal foreign objects in batteries are mainly caused by manufacturing defects. Since CT scanning technology is sensitive to high-density materials, it primarily detects metal foreign objects. Foreign objects in electrodes can lead to localized overheating during battery use, posing safety risks. Foreign objects in seals may cause poor battery sealing, leading to potential electrolyte leakage during use.

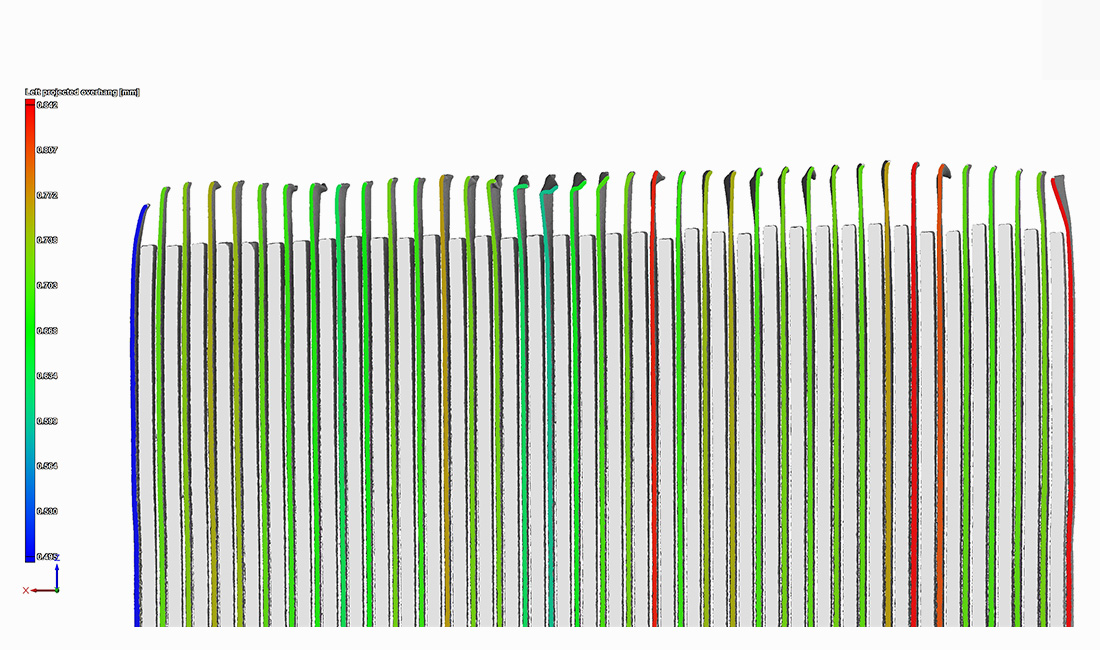

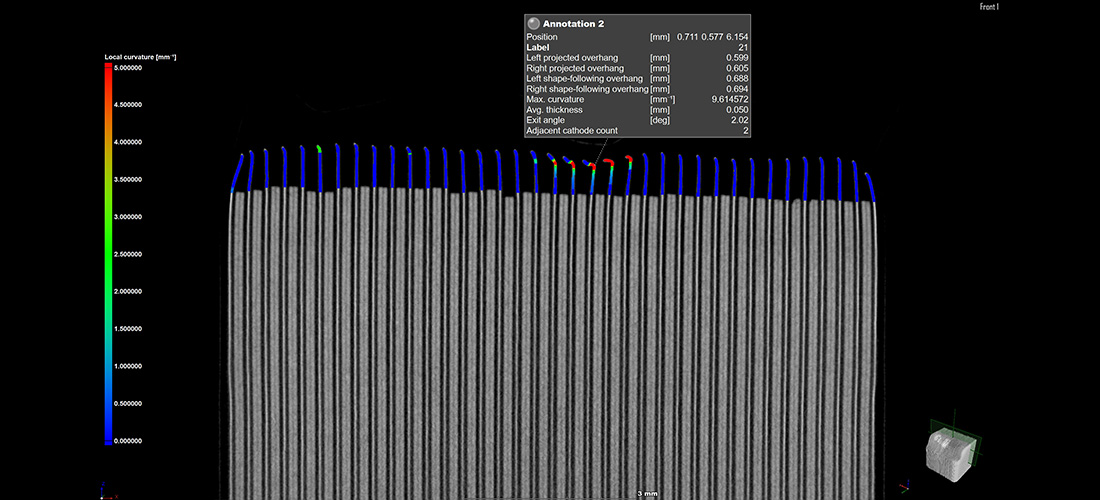

Laminated Battery - Curvature Analysis

Electrode curvature may cause differences in electrode coatings, such as compression of the coating facing the battery core and stretching of the coating facing the battery casing. This can induce compressive mechanical stress and lower porosity in the coating facing the core. Higher curvature (e.g., thicker electrode coatings) may lead to adhesion differences between the two sides of the negative electrode, affecting battery performance.

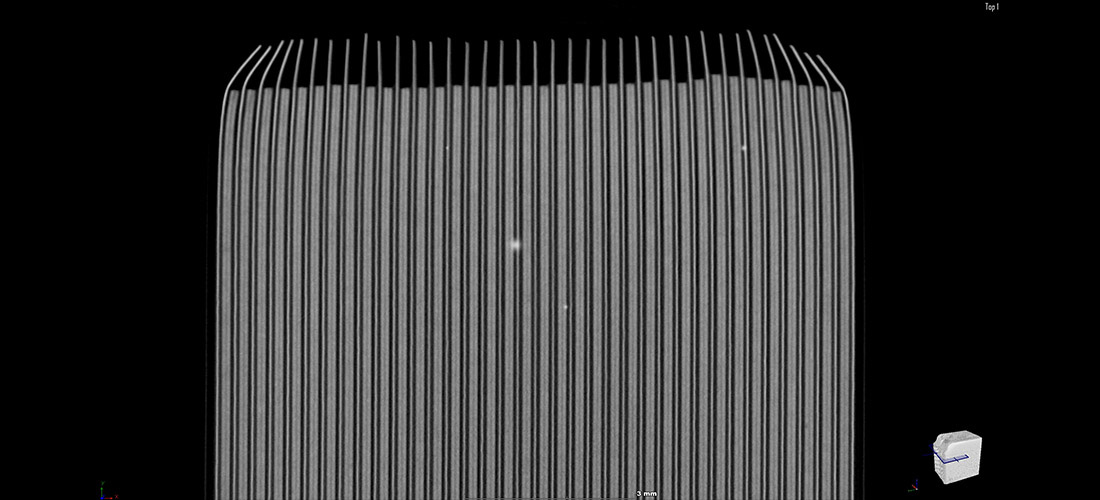

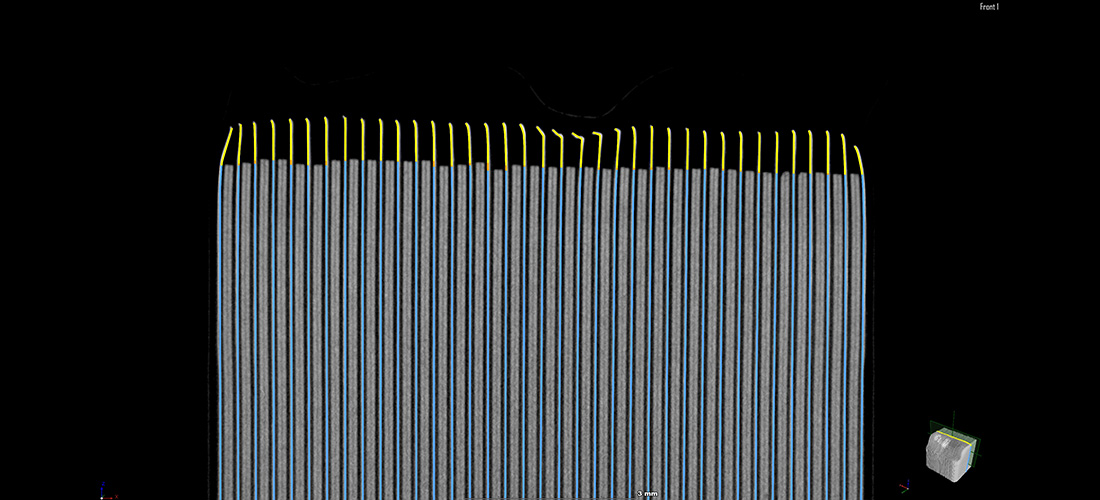

Laminated Battery - Shape Analysis

In power batteries, the presence of electrode wrinkles can indicate the overall regularity of the internal structure, related to the battery's manufacturing quality and usage level. Wrinkles create gaps between the positive and negative electrodes, reducing the effective contact area and affecting electrode reactivity during use, while increasing the risk of internal short circuits. The internal gaps caused by wrinkles also impact battery capacity and internal resistance, affecting heat generation and increasing consistency differences among cells in battery modules or systems.

Wound Battery - Curved Electrode Damage Analysis

Battery electrode structures may fracture due to manufacturing defects or charge-discharge cycles. Fractures typically occur at bending points inside the battery, such as the inner side of cylindrical battery windings or the inner side of pouch and prismatic battery windings and stacked electrodes. Electrode fractures cause the electrical connectivity near the fracture point to differ from other areas, leading to uneven current density distribution during charge-discharge cycles, resulting in slight heat generation imbalance and capacity loss. Since electrodes deform during cycling, the extent of fractures may expand due to overall electrode deformation.